Tung Oil Vs. Shellac: A Comprehensive Guide to Choosing the Right Wood Finish

Choosing the right finish is essential for enhancing the beauty of your wooden surfaces. Woodworkers have used Tung oil and Shellac as popular natural finishes for centuries to protect and beautify the wood.

But between Tung oil vs. Shellac, which is preferable? Tung oil is a good option if you want a natural finish that is hard, durable, and water-resistant. While Shellac offers a hard, durable coating to protect the wood, it is the easiest finish to apply but can be damaged by alcohol and other solvents.

Read on as we explore the differences between these finishes, their unique characteristics, and which one is better suited for your project.

Understanding Tung Oil and Shellac

Tung oil is derived from the nuts of the Tung tree (Vernicia fordii), native to China and East Asia. The oil is extracted through pressing, resulting in a natural and renewable finish for wood surfaces.

On the other hand, Shellac is a natural resin obtained from the secretions of the female lac bug (Kerria lacca). It is primarily found in the lush forests of India and Thailand. These secretions are harvested, processed, and transformed into a versatile resin finish.

The table below gives a brief overview of the differences between Tung oil and Shellac.

| s/n | Property | Tung Oil | Shellac |

|---|---|---|---|

| 1 | Source | Extracted from the nuts of the Tung tree. | Secretions of the female lac bug. |

| 2 | Application | Wood surfaces | Wood surfaces |

| 3 | Drying Time | Relatively slow drying time. | Fast drying time. |

| 4 | Appearance | Enhances the natural color of wood, improving its character and making it water-resistant. | Adds an amber or orange tint with a glossy finish. |

| 5 | odor | It has a mild, nutty smell | It has a distinct, alcohol-like odor. |

| 6 | Durability | Offers good durability for wood protection. | Provides moderate durability. |

| 7 | UV Resistance | Shows good UV resistance. | Poor UV resistance |

| 8 | Toxicity | Tung oil is generally non-toxic when fully cured. | Shellac is generally safe when dry. |

| 9 | Compatibility | Can be used with their finishes. | May not be compatible with certain finishes. |

| 10 | Type | Natural oil finish | Natural resin finish |

| 11 | Cost | $25 – $30 per quart | $11 per unit |

Tung Oil Vs. Shellac: Side-By-Side Comparison

Understanding their differences and functionality will enable you to make an informed decision for your next woodworking project. Look for the differences between these two finishes for the following aspects.

Compatibility

Tung oil’s versatility is favorable to woodworkers due to its compatibility with different finishes like polyurethane and varnish. Also, it offers varied aesthetics and added protection to your furniture. It suits various wood types and porous materials.

Shellac provides a beautiful finish, but its compatibility is limited. It is not suitable for certain modern finishes like water-based or solvent-based products. Also, it performs best over itself or under traditional wax finishes.

Water Resistance

Tung oil provides fair water resistance. Also, it acts as a protective barrier against minor exposure to moisture. It forms a breathable layer, allowing moisture vapor to pass through, preventing the wood from becoming overly dry.

Shellac, unfortunately, has limited water resistance. Prolonged exposure to water, spills, or high humidity causes Shellac to soften and dissolve. This potentially compromises the finish’s durability.

Appearance

Tung oil enhances the natural color and grain when applied to wood, revealing a warm, amber tone. The finish allows the wood’s natural beauty to shine through, providing a smooth, transparent appearance. Double coating with Tung oil produces a range of finishes from a soft satin sheen to a striking high-gloss shine.

Shellac lends a distinct appearance to wood surfaces. It adds an amber or orange tint, creating a vintage and traditional look. With its glossy finish, Shellac imparts a classic elegance to woodworking projects, making them stand out.

Heat Resistance

Tung oil boasts impressive heat resistance. This makes it an ideal choice for surfaces that come into contact with moderate heat exposure. The finish remains intact and does not easily soften, ensuring wood longevity and appearance.

Shellac has moderate heat resistance but is less durable than Tung oil in high temperatures. Extreme heat causes softening or damage to Shellac finishes on heat-prone surfaces.

UV Resistance

Tung oil excels in UV resistance, offering substantial protection against sunlight’s damaging effects. It prevents wood fading, discoloration, and degradation, making it ideal for indoor and outdoor applications.

Shellac has poor UV resistance, making it less suitable for outdoor use. Over time, Shellac degrades and discolors due to the effects of UV radiation, limiting its application in sunlit spaces.

Application and Ease of Use

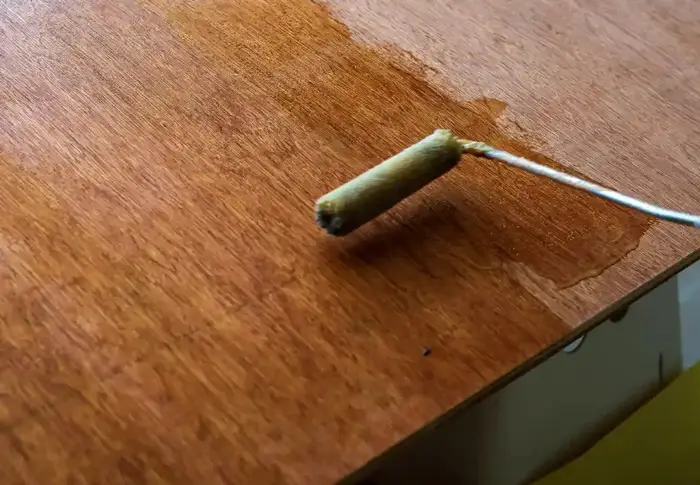

Tung oil application is straightforward, this is done by brushing or wiping it onto wood. Multiple coats are needed for the desired finish, with each requiring ample drying time compared to Shellac. The patient process yields a beautiful, durable result.

Shellac’s solvent-based nature allows easy application with a brush or padded cloth. Quick drying enables multiple coats in a shorter time, making it ideal for projects needing a speedy finish.

Durability and Protection

Tung oil provides a moderate to good level of durability. Also, it forms a protective layer on the wood surface that withstands regular wear and tear. Progressively, it offers resistance against scratches and minor impacts and some level of moisture protection.

Shellac provides moderate durability but does not match modern finishes in robustness. It guards wood from regular use but can’t withstand water, heat, or chemical exposure as well, making it more suitable for indoor applications.

Safety Considerations

Tung oil is safe after full curing, but proper ventilation is crucial during application due to its mild nutty odor. Check labels for additives and follow manufacturer instructions.

Shellac is safe when dry, but proper ventilation is necessary during application due to potent alcohol-based fumes. It’s essential to work in a well-ventilated area or wear a respirator for protection.

Drying Time

Tung oil has a relatively slow drying time, which varies based on environmental conditions. Depending on factors such as temperature and humidity, each coat takes several hours to a day or more to dry before the next coat is applied.

Shellac, in contrast, has a rapid drying time due to its solvent-based nature. Each coat typically dries within minutes, allowing for quicker application of additional coats. This quick-drying property makes Shellac an attractive option for time-sensitive projects.

Maintenance Requirements

Tung oil needs periodic maintenance to preserve appearance and protection. Over time, wear occurs, particularly in high-traffic areas. Applying a fresh coat when needed maintains the finish integrity based on usage and wear.

Maintaining Shellac finishes is simple, as they are easily re-coated to refresh appearance and protection. However, its durability does not match other finishes. This results in regular maintenance in high-wear and exposed areas.

Costs

The price of both tung oil and shellac depends on the distributor. It doesn’t have a specific price. Some distributors in made-in-china.com sell tung oil within the range of $10 to $100 per kg, another sells for $30.26 per kg. Shellac is sold between $24.45 to $36.50 per kg.

Pros and Cons of Tung Oil and Shellac

Both Tung Oil and Shellac have their pros and cons. Check them out to understand their aspects of use and limitations.

Pros of Tung Oil

- It is food-safe, non-toxic, and safe for the environment.

- Simple application with deep wood penetration.

- Enhances the natural beauty and color of wood, bringing out its grain patterns.

- Offers good heat and UV resistance, protecting wood from sun and heat-related damage.

- Provides a durable and long-lasting finish with the ability to withstand wear and tear.

- Can be applied to various wood types and porous materials.

- It finds suitability in various applications, such as handmade wood bowls, plates, butcher blocks, cutting boards, etc.

Cons of Tung Oil

- Achieving a desirable satin sheen often involves applying up to 5 coats, and it takes more time to harden.

- Darkens the wood slightly, altering its appearance

- Tung oil requires reapplication every six months or periodically to maintain its luster.

Pros of Shellac

- Derived from natural resin secreted by the female lac bug, making it a renewable resource.

- Dries quickly, allowing for efficient application of multiple coats in a shorter time.

- Shellac remains non-yellowing with resistance to UV rays from the sun as time passes.

- Compatible with various finishes.

- Being a natural and non-toxic finish, Shellac is safe for both children and pets.

- Its versatility allows it to function as a moisture barrier, sealer, and polish, catering to multiple purposes.

- Offers a warm and classic finish that enhances the wood grain.

Cons Shellac

- Its longevity is shorter compared to other finishes, and it must be applied within six weeks after blending with denatured alcohol.

- Not as durable as some modern finishes, leading to wear and the need for regular maintenance.

- Strong alcohol-based fumes during application, requiring proper ventilation and safety precautions.

- Vulnerable to damage caused by heat, solvents, water, and chemicals, making it less suitable for outdoor or high-heat applications.

FAQs

Here are questions people also ask when comparing Tung oil and Shellac.

Does Tung oil go moldy?

Tung oil offers a water-resistant finish, resistant to mold and rancidity. It’s safe for diverse surfaces and wood grain due to its lack of distillates and additives.

How to tell if Tung oil is bad?

If Tung oil has gone bad, an evident indication is a rancid odor. Additionally, it may thicken, posing difficulties during wood finishing.

Can Tung oil and Shellac be used together in a single finishing project?

Applying Shellac over a Tung oil finish is possible. But it’s crucial to note that you must wait for the Tung oil to fully cure. This process typically takes around a week or more to ensure optimal results.

Final Word

This article has clearly discussed the key differences between Tung oil and Shellac finishes. These differences majorly lie in their source, appearance, compatibility, water resistance, application method, drying time, durability, and maintenance requirements.

Tung oil is derived from the nuts of the Tung tree and excels in UV and heat resistance. It offers a durable, natural finish with various aesthetic options. Shellac, derived from the lac bug’s resin, provides a beautiful, glossy appearance but lacks durability and water resistance.

To make an informed decision, consider your wood type, project requirements, desired aesthetics, and maintenance preferences. Tailor your choice to achieve the perfect finish for your woodworking masterpiece.