How To Thin Polyurethane – Everything You Should Know

Sometimes, it’s difficult to apply polyurethane because of its high viscosity. In this case, adding a thinner makes the poly easier to apply by making it less dense so it can flow more freely.

Want to know how to thin polyurethane? Gather the tools and materials needed, read the manufacturer’s instructions, and clean the mixing container. Once that’s done, measure and add the recommended ratio of solvent and polyurethane to the mixing jar. Finally, stir the mixture and test its consistency.

Read on to learn how to thin polyurethane, which thinners to use, the consequences of over-thinning, and tips for the best results.

Tools And Materials You Need To Thin Polyurethane

Some of the tools and materials you need to gather before thinning polyurethane include;

- Polyurethane

- Measuring container

- Rags or paper towels

- Mineral spirit or water

- Glass jar

- Gloves

- Respiratory mask

- Paint filter

- Test area

How To Thin Polyurethane?

Once you gather the necessary tools and materials, here’s a step-by-step guide on how to thin polyurethane;

Step One: Check the manufacturer’s instructions

Read the polyurethane label for instructions on which solvent to use and how much to use to achieve the best results.

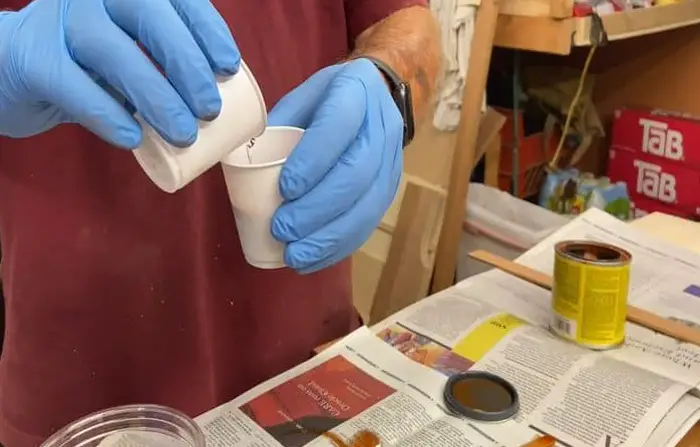

Step Two: Clean the mixing container

Clean the container that you intend to use to thin the polyurethane. Cleaning is important because it helps eliminate any dust or dirt that may introduce blemishes in your polyurethane.

Step Three: Stir the polyurethane

Before you measure and pour out the polyurethane, shake and stir it vigorously to ensure any settled particles mix in with the liquid.

Step Four: Pour in the polyurethane

Measure the amount of polyurethane you want to thin and pour it into the clean mixing container. It will help you determine how much solvent to use depending on the manufacturer’s instructions.

Step Five: Add the solvent

The amount of solvent you add to the polyurethane depends on the recommended ratio. Measure the required amount of solvent and add it to the mixing container.

Since there are two types of polyurethane, water- and oil-based, you must use the appropriate solvent type to achieve the desired result. For water-based polyurethane, simply add the required amount of water as the thinning agent.

For oil-based polyurethane, use mineral spirits or any oil-based solvent recommended by the manufacturer. Add the solvent according to the ratios instructed by the manufacturer.

Step Six: Stir the mixture

Use a clean stirring stick to stir and mix the polyurethane and solvent mixture for a few minutes until you get the required consistency. Stir the mixture slowly at a constant rate to avoid creating bubbles.

Step Seven: Test

Apply the thinned polyurethane on a small test area and give it time to dry. After drying, assess the test area for any sign of bubbles, exposed patches, or streaks. If there are no blemishes, the thinning process is successful.

If the test area has patches and streaks, the polyurethane is probably too thin. Add and stir small amounts of the leftover poly until you achieve the correct consistency. Conversely, if the thinned poly is too thick, add some solvent and mix it in to achieve the required texture.

Step Eight: Apply the polyurethane or store it

Once you have successfully thinned your polyurethane, apply it using a spray gun, paintbrushes, or even a cotton cloth. If you intend to use the poly later, store it in an appropriately labeled air-tight container.

Why Is It Important To Thin Polyurethane?

Though you can use polyurethane without thinning it, there are several reasons why someone may choose to thin it;

Ease of application

Thinning polyurethane makes it easier to apply by improving flow. There is a slimmer chance of bubbles or brush marks forming when using thinned poly. Hence, a thinner consistency allows you to achieve a smooth and even finish without streaks.

Quick drying time

A surface dabbed with thinned polyurethane dries much faster than a surface smeared with unthinned polyurethane. Quick drying times are advantageous, especially when applying multiple coats within a short duration.

Improved penetration

Due to lower viscosity, thinned polyurethane penetrates wood much better than the unthinned version. Hence, using thinned poly decreases the chances of making woodworking mistakes.

Application technique

Some application techniques, such as spraying, require you to thin polyurethane because otherwise, the process would be highly inefficient.

What Are The Effects Of Over-Thinning Polyurethane?

While thinning polyurethane offers several benefits, over-thinning has dire consequences. The consequences include the following;

1. Reduced durability

Excessive thinning can weaken polyurethane’s protective properties because the applied coat will be too thin. Hence, the finish will be less durable, have lower water resistance, and be more susceptible to damage like scratches.

2. Messy work area

Over-thinned polyurethane is extremely runny, so it will drip from slanted or vertical surfaces, making the work area extremely messy.

3. Poor coverage

When over-thinned, polyurethane has fewer solid particles per unit volume, meaning you need more coats to achieve the desired finish.

4. Difficult to apply

When polyurethane is too thin, it has low viscosity, making it flow much more freely. This easy-flowing, runny nature makes applying thin poly a difficult challenge.

5. Inconsistent appearance

Over-thinning can cause uneven absorption across the wood surface, forming patches, blotches, and streaks that create an inconsistent appearance.

6. Reduced gloss

Sometimes, when the polyurethane is too thin, the coating will appear less glossy than expected. It may even have discoloration in some areas.

Polyurethane Thinning Tips

Some tips that will enable you to get the best results when thinning polyurethane include;

Use the right type of thinner

It’s important to use the correct thinner type depending on the polyurethane available. Using water-based thinners on oil-based polyurethane or oil-based thinners on water-based polyurethane will lead to a huge mess of clumpy poly.

Avoid shaking the mixture

When thinning polyurethane, stir instead of shaking the mixture. Shaking is generally bad because it introduces air bubbles into the poly, which can lead to a poor finish when applied to wood. Conversely, stirring creates a smooth mixture that ensures a neat finish when applied to wood.

- Nail the solvent-to-polyurethane ratio

Always refer to the manufacturer’s instructions about ratios when thinning polyurethane. However, if you don’t have access to the instructions, you can use a 3:1 thinner-to-polyurethane ratio. Remember that this ratio is not set in tone, so feel free to experiment until you achieve the best consistency.

- Always test

Before applying thinned polyurethane to a project, it’s important to test it. Testing allows you to see what the finish will look like and gives you a chance to adjust the poly’s consistency to your desired level.

Safety Precautions When Thinning Polyurethane

Working with polyurethane is risky, so taking precautions to protect yourself when thinning polyurethane is important. Some of the general safety measures that will ensure your safety include;

- Work in a well-ventilated area or outdoors if that’s possible. Having adequate ventilation is important because free airflow helps disperse the smelly fumes emitted by polyurethane.

- Avoid smoking or having any open flames in the working area because some of the solvents used to thin polyurethane are highly flammable.

- Keep children and pets away from the working area to prevent any issues related to accidental ingestion of polyurethane.

- Wear a protective respiratory mask to avoid inhaling fumes. Polyurethane’s fumes contain VOCs (volatile organic compounds) that can cause respiratory problems when inhaled.

- Wear safety goggles to protect yourself against irritation caused by splashes and fumes.

FAQs

Here are some answers to common questions about thinning polyurethane.

Q: Can you use acetone to thin polyurethane?

You can use acetone to thin polyurethane, but it may not produce the best results since it is a paint remover. Acetone evaporates quickly; hence, it sometimes causes the polyurethane finish to crack.

Q: Can you use denatured alcohol to thin polyurethane?

Yes, you can use denatured alcohol to thin water-based polyurethane. However, since this solvent is highly effective, you should be careful to avoid over-thinning the poly.

Q: What thinners are suitable for polyurethane?

When thinning water-based poly, your best option is water. As for oil-based polyurethane, there are many solvents you can use, including;

- Mineral spirits

- Lacquer thinner

- Turpentine

- Paint thinner

Conclusion

In summary, thinning polyurethane is straightforward, provided you have the right tools and solvent. Once you have a clean container and a stirring stick, add the recommended ratios of solvent and poly before stirring. You should always test the thinned poly to ensure you’re content with its consistency.

Some tips to achieve good results include never shaking the mixture to avoid introducing bubbles, always using the right thinner, and following manufacturer instructions. Since working with poly can expose you to harmful fumes, always wear protective gear and work in well-ventilated rooms.